Pointers to keep your greenhouse facility running smoothly, prevent major malfunctions that can hinder plant health, and help reduce overall expenses.

Hemp may be the newest crop to be grown in greenhouses, but the challenges of rearing a successful crop can be met with current technology and methods refined by the commercial horticulture and vegetable industries over the decades. Whether a crop is grown for cannabidiol (CBD) or for other cannabinoids— or whether the greenhouse is utilized for mother plants or all growth stages—the inputs such as root substrate, fertilizer and containers used for other crops are proving suitable for hemp. Likewise, plant culture protocols of rooting, topping and irrigating are not unique to hemp. What may differ is the grower’s experience using a greenhouse for scaled production. A greenhouse is more machine than building, always running, subject to a dynamic environment surrounding it as well as the maintenance of components within. Below are tips for maintaining an efficient greenhouse that I’ve learned in 30 years of managing research, retail and wholesale facilities.

System Investments

1. Buy the most sophisticated environmental control system (ECS) you can afford, maybe even spending more than you can afford. All efficiencies made to the structure and equipment will pale in comparison to the benefits this investment will deliver. Greenhouse cropping involves perishable products growing in a dynamic environment. Think of your ECS as your greenhouse’s brain helping you manage this living system. Maintaining temperatures or triggering irrigation for optimum growth can involve as many as six environmental variables. Excellent ECS systems can alert a grower to disease conditions, predict yields and even monitor labor efficiency. Your savings come from automating labor required to monitor, track and constantly adjust the environment, and from the prevention of catastrophic crop failure. Other benefits include helping to ensure optimal conditions for maximizing plant health and yield.

2. Integrate as much equipment as you can—not just heating and cooling, but also boilers, humidifiers, circulation fans, lighting and shading. The best ECS systems have the capability to anticipate the need for activating equipment before the growing environment drifts out of bounds. The more equipment is integrated in this way, the better the environment can be maintained, both efficiently and cost effectively.

3. Control lighting and shading together using weather data, which enables you to set a daily light integral target (light sum) in varying weather and seasons, and—as evidenced from my own controlled experiments with multiple greenhouse bays—reduce the hours your lights run by about 25% (rather than keeping them on the standard 16 hours per day). This can also mean about 25% savings in energy costs spent on lighting.

4. Track operational minutes for each piece of equipment. This allows you to quantify energy-saving initiatives and reduce equipment over-cycling that normally goes unnoticed.

5. Buy a good photosynthetically active radiation (PAR) light meter. Growers learn a great number of things when they first begin measuring light: the difference between cloudy and sunny weather, how much light the glass or plastic filters, the lack of uniformity across a room, the dimness under the canopy. A PAR meter allows you to compare your environments against published research on optimizing growth. Make sure it is designed for PAR and not for footcandles, which are more tuned to the human eye. The same learning takes place with a handheld spectrometer that measures both light spectrum and quantity.

6. Keep small data loggers on hand for measuring temperature and humidity. If you are observing non-uniform plant growth, these can identify microclimates that may be responsible and allow you to adjust air circulation or other equipment to resolve the problem. They can also measure inside propagation domes and inside drying or curing areas. It’s important to keep these out of direct light, which heats the sensor and affects accuracy.

Climate Control Upkeep

7. If you use hot water for your heaters rather than gas, confirm that the valves are truly opening by using an infrared temperature gun pointed at the unit heaters or the radiant pipes. This makes your pre-winter check go quickly. Sometimes the oscillating handle on the outside of a heating valve moves while the mechanism inside has seized. Hot water valves stuck open can go unnoticed. A good control system will monitor the temperature of the heating water to identify this problem. Another sign of this is a greenhouse that is cooling when it normally wouldn’t need to, such as at night.

7. If you use hot water for your heaters rather than gas, confirm that the valves are truly opening by using an infrared temperature gun pointed at the unit heaters or the radiant pipes. This makes your pre-winter check go quickly. Sometimes the oscillating handle on the outside of a heating valve moves while the mechanism inside has seized. Hot water valves stuck open can go unnoticed. A good control system will monitor the temperature of the heating water to identify this problem. Another sign of this is a greenhouse that is cooling when it normally wouldn’t need to, such as at night.

8. You can better control cooling with multiple exhaust fans operating independently (rather than all fans being on or off simultaneously) and by staging the appropriate amount of equipment for the current cooling demand. Investing in variable-speed fans can take this staging one step further than using a one- or two-speed fan while reducing ambient noise. (For example, a two-speed fan may operate at full speed and 50% speed, when perhaps only 25% of full speed is required; a variable speed fan that can run at 25% speed would therefore reduce energy consumption in this case.)

9. Routine belt replacement is essential for fans, as is having a spare motor on hand for quick change-out; otherwise, you may have to wait 48 hours for one to arrive.

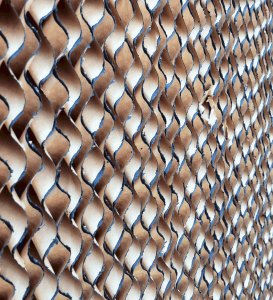

10. When selecting evaporative cooling pads, opt for a brand with a black, half-inch coating on the greenhouse-facing fluted edges. The coating prevents algae and makes cleaning as easy as a hose-off. In fact, I used to pay extra to have pads coated on both sides to prevent scale (hard water) buildup on the exterior-facing side.

11. However, most of my algae problems were solved by disabling the pumps that were wetting these pads overnight. Other managers have found eight hours of drying to be suitable, but I had to leave them off for 11 hours (8 p.m. to 7 a.m.). This saved me the time and expense of adding disinfectant weekly to my two-dozen pad reservoirs. Time and expense depends on what disinfectant you use, labor costs and the number of reservoirs. At our research greenhouse at Purdue, which had 28 reservoirs, this saved $20 to $80 per week in disinfectant, depending on the formulation, and .75 hours of labor, while also reducing employee exposure to concentrated chemicals.

12. Adjust the water flow over your evaporative pads to wet the entire pad without splashing the floor.

13. Repair leaks in gutter seams with clear butyl gutter sealant dispensed with a caulk gun.

14. Clean the pipes of the evaporative pad system, as well as the reservoir, two to four times per year, as the primary cause of pump failure is sediment clogging the intake. The pipe that distributes water above the pad may become clogged with scale, particularly at the end farthest from the pump. Bore out any clogged holes in the pipe.

15. It is vital to bleed off some of the reservoir water as the pump runs. Otherwise, as the water evaporates off the pad, the minerals (mostly calcium) left behind will accumulate in the reservoir and eventually on the pads themselves. Pads calcified this way will not only cool less efficiently, but also grow so heavy as to pull the pad frame away from the wall.

16. Check and adjust the bleed-off valve to make sure it is removing at least 1/2 gallon per minute to prevent mineral buildup, potential clogging and reduction in cooling capacity.

17. Vibration over time may change this flow, so check the bleed-off valve monthly during the cooling season. For my systems, a sufficient flow rate corresponded with a water stream about the width of a pencil. More flow won’t hurt, but it wastes water.

If your facility is in an area near cottonwood trees, their seed fluff will clog the back of evaporative pads. Poorly managed bleed-off valves can cause the fluff to become calcified like an impenetrable petrified spider web, which will ruin the pads.

Managing Airflow

18. Air circulation in a greenhouse—a separate concept from ventilation—is best achieved with horizontal air flow (HAF) fans designed for this purpose. HAF fans need to be sized correctly for the cubic feet of the air mass and installed in sufficient numbers to make a circular current in your greenhouse. Air has weight, so momentum will carry it with little energy input from the fans once it flows in this pattern. Avoid using standard box or oscillating fans, which create localized turbulence rather than the desired river of air.

18. Air circulation in a greenhouse—a separate concept from ventilation—is best achieved with horizontal air flow (HAF) fans designed for this purpose. HAF fans need to be sized correctly for the cubic feet of the air mass and installed in sufficient numbers to make a circular current in your greenhouse. Air has weight, so momentum will carry it with little energy input from the fans once it flows in this pattern. Avoid using standard box or oscillating fans, which create localized turbulence rather than the desired river of air.

The total fan capacity in cubic feet per minute (fpm) for this circulation pattern should equal one-fourth of the greenhouse volume, according to the text “Greenhouse Engineering,” a Cooperative Extension publication by Robert A. Aldrich and John W. Bartok, Jr. Ideally, these fans should be integrated into your control system so that they shut off when the ventilation fans are cooling the room. Otherwise, they will create turbulence that will disrupt the parallel flow across the greenhouse, reducing the cooling efficiency.

19. Circulation air velocity should be a minimum of 50 fpm to create a healthy microclimate around leaves. Higher may prove better, as research has indicated that downy mildew can be minimized by maintaining an air velocity during the dark period of 75 fpm to 300 fpm.

Cleanliness

20. Keep the facility walls and roof clean. Estimated light transmission loss from dirty greenhouse roofs ranges from 5% to 10%.

21. Hire an insured, professional greenhouse service team to clean the walls and roof. For gutter- connected houses, you can purchase robotic units (which roll along the peaks, scrubbing and rinsing). If you take this task on yourself, rent power lifts and have your staff certified to use them for pressure-washing the glass or rigid plastic, at the very least. Avoid using ladders or “walking the gutters,” since there is nothing to tie yourself to for safety.

22. Clean sidewalls, inside and out, annually. Glass or rigid plastic with heavy scale deposits can be pre-treated with a sulfuric acid product registered for greenhouse use before pressure-washing. For routine glass cleaning, use glass cleaner and squeegees on extension handles for best results. Avoid getting cleaning solutions on plants.

Lighting

23. Track operation hours of your bulbs, either in your written log or using the control computer, to ensure you change them before their output decays below 80%. An old High Pressure Sodium (HPS) bulb will often appear darker orange when illuminated than a newer one. HPS bulbs that sporadically turn off every few minutes need to be replaced immediately before they burn out the ignitor in the fixture. Fixtures with loud, buzzing transformers are a true nuisance to your employees who work in the room several hours per day. Failing fixtures can be repaired, but only by someone certified to discharge a capacitor and work with high voltages. (LED fixtures, however, don’t require the above maintenance.)

Tip-Top-Shape Shade Systems

24. Employing motorized shade fabric systems is a great way to regulate light intensity and daily light integral; but these systems are expensive to repair, as the labor costs to make even the smallest fix is several times the cost of the component, especially if you need a power lift to reach it.

Therefore, it pays to buy quality fabric and maintain the system routinely. Buy fabric from established manufacturers. Consider fabric that retains heat, as this will both save energy and lessen the chance that plants will form condensation at night if their temperature drops below the dew point by emitting heat toward the cool glass. (Bonus tip: Consider a white fabric designed to diffuse light. Research suggests that white fabric will increase the number of photons reaching the plants’ lower foliage.)

25. Lube shade curtains’ rack and pinions annually with a dry moly aerosol lubricant spray. Avoid grease, as it allows dust and grime to collect and gum-up the gears.

26. Inspect your curtains to make sure circulation fans are not blowing directly on them. Fans blowing on them will cause them to vibrate constantly on the support wires, quickly wearing them thin.

The ‘Lightning Round’—More Tips!

Below are more tips for an efficient building and operation that don’t necessarily fit into other categories.

27. Consider contracting annual maintenance to an experienced greenhouse company. This resolves safety issues and allows you and your staff to concentrate on growing and delivering quality product to your customers. It will ensure the maintenance is performed, as these tasks are typically not prioritized, despite best intentions.

28. The same dry moly aerosol lubricant mentioned for shade curtains’ rack and pinions should be applied to vent rack and pinions annually.

29. Apply floor coatings to cement, making it resistant to algae buildup. The room needs to be empty and dry to apply the coating, and it takes two to three days for application and drying, but it is well worth it, even if only in your propagation area or under evaporative pads.

30. Irrigation pipes and hoses should be cleared of biofilms at least twice annually using a product labeled for this use. This will reduce clogging of drippers and nozzles.

31. Label each outlet with the circuit breaker that controls it. I use a labeler with weatherproof adhesive printing tape to color-code them according to outlets that are controlled by timers (versus those that are always on). These labels will improve safety, communication and efficiency of repairs and installations.

32. Use signal tapes and flags to improve communication between staff about a clogged dripper, for example, or which plants have pests, which plants are being flushed, etc.

33. Laminate signs to drastically improve their look and longevity.

34. Make repairs more efficient by maintaining a parts list and keeping spare parts on hand.

35. Assemble job-specific tool kits for grab-and-go responses to problems, including a tool kit for plumbing repairs and a tool kit for electronics repairs. Also, an emergency submersible pump with flexible hose fittings can quickly replace an evaporative pad pump until you can plumb one in properly.

36. Consolidate maintenance and repair records in a format that can be shared with your team members and is available by smartphone. Develop your own Google Doc, or consider using another available third-party software.

37. Buy a rivet gun to help you fix loose louvers.

38. Shield anything made of plastic from direct sunlight exposure to protect these items from cracking or disintegrating. Reflective bubble wrap is a good solution.

39. Invest in rolling safety ladders with side rails to reach high places.

40. Consider buying a used power lift from an equipment rental company if you can’t afford a new one. I bought a used lift for $6,000 that has lasted more than 10 years.

Constant monitoring and maintenance can help you and your team avoid major mishaps in your greenhouse, help your environmental systems run more efficiently and effectively, and foster healthy plant growth along with a healthier bottom line.

Robert Eddy is a consultant and former Purdue University greenhouse manager.

Note: This article was updated and adapted by the author from a two-part feature series that was originally published in Hemp Grower’s sister publication Cannabis Business Times.