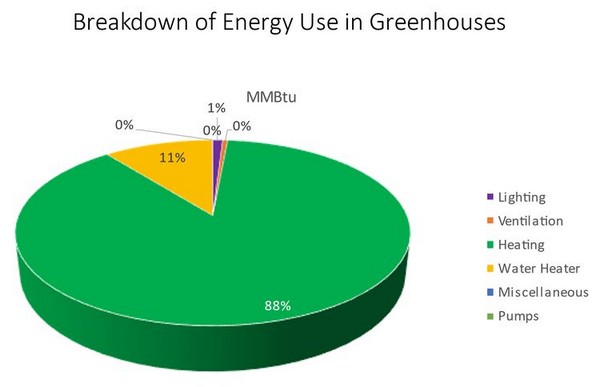

As greenhouse businesses prepare for the busy late winter and spring season, November is the time for greenhouse operations to finalize any facility improvements and the installation of new energy-efficient technologies. Energy bills are typically the second largest operational expense – behind labor – in a greenhouse business. According to a Michigan State University study, 88% of the energy used in greenhouses is for heating, and 11% is for water heating (Figure 1).

Therefore, it is especially important that greenhouse crop production businesses keep their systems updated to maintain profitability. In the new educational video, “How to Use Less Energy to Heat a Greenhouse?”, Michigan greenhouse growers share their insights on how to save energy:

According to Michigan State University Extension, the best ways to save energy in greenhouses are to:

- Install and maintain infrared (IR) anti-condensate polyethylene film. When growers install an IR film as the inside layer of a double-poly greenhouse, less heat is lost through the glazing at night. An anti condensate film is also recommended to decrease the accumulation of water drops on the plastic, which can decrease light transmission and wet the foliage of plants below. To maintain light transmission and replace brittle plastic, most poly films need to be replaced every three years.

- Install high-efficiency unit High-efficiency heaters are usually more than 93% efficient and use less energy compared to older, less-efficient technologies.

- Install and maintain horizontal airflow (HAF) fans. Fans that move air horizontally throughout the greenhouse help to keep the air within the greenhouse uniform, allowing for peak performance of heating and environmental control systems. They also decrease the vertical temperature gradient by mixing some warmer air toward the top of the greenhouse with the cooler floor temperature.

- Maintain boilers and hot water heaters. Regular boiler and hot water heater maintenance, scheduled testing, and updates like heat recovery systems help improve energy efficiency and lifespan of boilers. With hot water for root zone or under bench heating increasing in use, boilers and hot water heaters have expanded their energy impact. General facility air heating temperatures can be reduced.

- Install environmental control systems. Environmental control systems (for example, Argus, Priva, QCOM) automatically control the heating systems, vents, fans, and lighting systems to keep a greenhouse at the desired temperature and turn lights on and off, when needed. These systems, as well as setting stages of heating (running most efficient heating before starting less-efficient heaters), reduce energy usage.

- Install thermal heat curtains. A well-maintained curtain system reduces the cubic feet of air that a heating system needs to warm, prevents heat from escaping through the roof, and keeps the warmth where growers need it, namely the plants.

- Install root-zone heating. Root-zone heating, also known as under bench or floor heating, heats plants from below, thereby keeping the roots and the plant canopy warmer than the air above it. This allows you to reduce the air temperature in the greenhouse while still maintaining adequate temperatures for plant growth and development.

There are also ways to limit energy usage for heating without the addition of new technology: reducing air leaks, growing cold-tolerant plant species, and reducing crop production time. Many of these energy-efficient technologies have a relatively short return on investment (e.g., one to three years) and can decrease greenhouse operational costs.

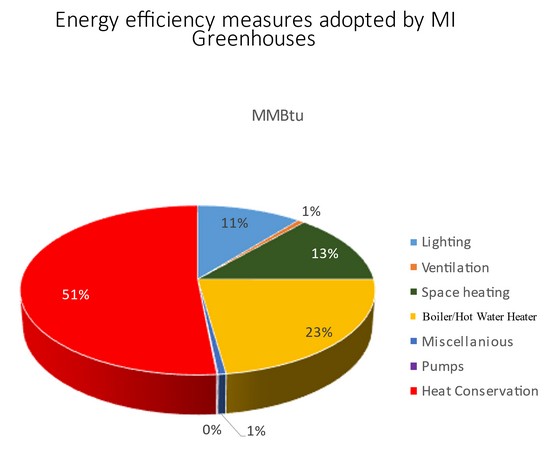

In addition, there are often rebates through utility companies that can further reduce the installation costs. In Michigan, the most common energy efficiency measures adopted by Michigan greenhouses are those to conserve heat (e.g., energy curtains, 51%), boiler and hot water heater upgrades (23%), and space heating upgrades (13%; e.g., high-efficiency unit heaters).